There may be a hole in your boat, and you don’t even know it. Maybe you’ve seen a recent slide in your operating profit margin. Or you lost a bid to a competitor whose price seemed impossibly low—and you’re left wondering if they know something you don’t. Success can mask inefficiencies, and even when margins look healthy, you might have a nagging feeling that things could be better.

If any of the following scenarios sound familiar, it might be time to consider a new approach:

- You’re preparing a quote for a major customer and hesitate. Should you go lower to win the business? You’re not entirely sure where your walk-away price is.

- Your “best” customer—the one who orders the most—keeps asking for price concessions. You give them a discount because of the volume, but something doesn’t feel right about the deal.

- You discover too late that a product line you’ve been pushing hard is actually losing money once you factor in all the support it requires.

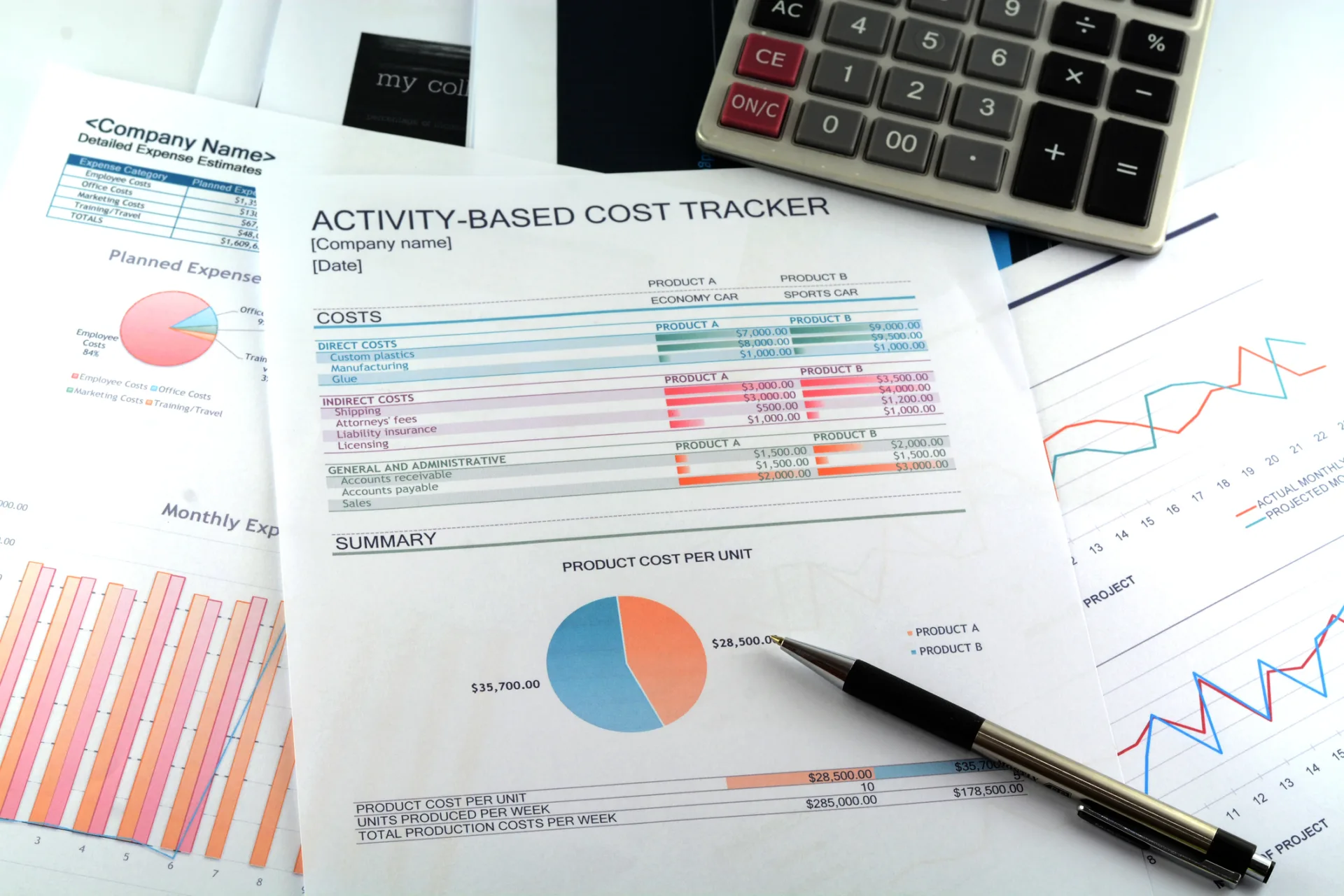

In this article, we’ll delve into one costing method, activity-based costing (ABC), that can help uncover your true costs to help you make smarter, more profitable business decisions.

The Data Gap in Manufacturing

When you can’t see clearly, how can you make the best decisions about where to steer? Unfortunately, many small and mid-sized manufacturing companies don’t have the level of data required to understand their actual costs. They have financial statements, but financial accounting and management decision-making require different tools and approaches.

The cost of goods sold (COGS) calculation on your income statement serves an important purpose—matching costs to corresponding revenue generated within the same accounting period. But COGS doesn’t tell you which products are profitable, what your true capacity constraints are, or where inefficiencies are hiding in your operation.

To uncover these insights, you need a different lens—one that reveals how resources are actually consumed in your business.

Why Traditional Costing Falls Short

Let’s look at a simple example. Suppose you manufacture two products:

Product A: is a high-volume, straightforward item that runs for hours with minimal setup or handling. Your machines hum along efficiently, requiring little oversight.

Product B: is a low-volume, complex item requiring frequent setups, multiple quality checks, specialized handling, and considerable engineering support.

Traditional costing systems allocate overhead based on a single metric—typically direct labor hours or machine hours. Using this approach, both products might appear to have similar costs per unit because they use comparable machine time.

But that’s not the reality on the shop floor. Product B is consuming far more resources: your setup crew’s time, your quality inspector’s attention, your purchasing department’s effort managing specialized materials, and your engineer’s expertise solving production issues.

You might be pushing hard to sell more of Product B, not realizing it’s the anchor dragging down your profitability.

Activity-Based Costing: A Better Way to See Your True Costs

Manufacturing companies typically have a solid grasp on direct costs—the materials and labor that go directly into each product. It’s the overhead—everything from machine setups to quality inspections to purchase order processing—that often falls beneath the radar. And that’s where ABC really shines.

Here’s how it works:

- Identify specific activities that consume resources (machine setups, quality inspections, purchase order processing, engineering changes, material handling, etc.)

- Determine the cost of performing each activity (What does it cost us every time we do a machine setup? Every time we process a purchase order?)

- Allocate costs to products based on how much of each activity they actually consume (Product B requires 12 setups per month, while Product A requires 2)

The result is a far more accurate picture of what each product, customer, or job costs to produce.

What Better Cost Data Enables

With more accurate cost information, you gain the clarity to make strategic decisions that directly impact your bottom line:

Price with confidence.

ABC reveals which products are truly profitable and which are subsidized by others. You can set prices that cover actual costs and achieve desired margins—and know precisely where your walk-away point is in customer negotiations.

Real-world impact: Many manufacturers discover that their highest-volume customers aren’t their most profitable ones. Armed with this knowledge, you can strategically pursue the right business, negotiate from a position of strength, and avoid the trap of “buying revenue” at the expense of profit.

Optimize your product mix.

Not all revenue is created equal. ABC helps you identify which products deserve more focus and resources, and which might be candidates for repricing, redesign, or even discontinuation.

You might discover that hidden costs make your flagship product relatively less profitable than another product line you’ve underestimated.

Improve cost control and operational efficiency.

ABC provides a clear link between costs and the activities that drive them. This transparency allows you to identify inefficiencies by pinpointing costly processes that are ripe for improvement.

For example, you might discover that excessive setups are killing your profitability on certain products. With this insight, you can explore solutions: batch size adjustments, production scheduling improvements, quick-change tooling investments, or setup reduction initiatives.

Make better strategic decisions.

With granular cost data, you can confidently answer questions like:

- What would be the impact of holding more inventory (or less)?

- Should we produce larger runs?

- Would outsourcing part of the production process improve profitability?

- Do we have the capacity to take on a new opportunity—and at what cost?

- Should we invest in automation for this product line?

Each of these decisions becomes clearer when you understand the true economics of your operation.

Getting Started with Activity-Based Costing

If you’re thinking ABC sounds complicated or expensive, here’s the reality: You don’t need to cost every single activity on day one.

Many manufacturers start with a pilot approach:

- Focus on overhead categories that represent the largest costs or the biggest unknowns.

- Begin with a subset of your products—perhaps your top revenue generators or those you suspect might be problematic.

- Start simple and refine over time as you learn what matters most in your operation.

The investment—in time and resources—typically pays for itself quickly when you make even one or two better-informed decisions about pricing, product mix, or process improvement.

The Bottom Line

You can’t manage what you don’t measure, and you can’t measure what you can’t see. Traditional accounting gives you compliance and financial reporting. Activity-based costing gives you visibility into the actual economics of your business.

If you suspect there’s a hole in your boat—or even if everything seems fine but you wonder if it could be better—it’s time to get the data that reveals what’s really happening below the waterline.

Ready to explore whether activity-based costing is a good fit for your operation? Start by asking yourself: Do I know with confidence which products, customers, or jobs are most profitable? Then reach out to Copeland Buhl’s accountants and business advisors to explore exactly where your profitability comes from—and where it’s leaking away.